For more than one hundred years, highway vehicles have been powered by internal combustion engines that burn gasoline or diesel fuel. In the last 20 years, however, vehicles powered by alternative fuels have proliferated, viewed as a means of reducing the world’s dependence on fossil fuels, lowering fuel costs, and lessening environmental pollution. The most widely used alternative vehicle fuel is electricity.

By 2000, vehicles combining an internal combustion engine with an electric motor, known as hybrid-electric vehicles (HEVs), had been introduced to the US market. The very first of these were the Honda Insight in 1999 and the Toyota Prius in 2000. Hybrid vehicles relied on the electric motor as a secondary power source (to assist the internal combustion engine in acceleration, for example) and also to capture the kinetic energy from braking that would ordinarily be converted to heat and lost. A nickel–metal hydride (NiMH) battery, charged by the internal combustion engine, powered the motors in the early hybrid vehicles. The output of the motors in these vehicles was small, ranging from 13 to 40 horsepower (hp). Some manufacturers continue to use NiMH batteries in their hybrid electric vehicles.

Plug-in hybrid electric vehicles (PHEVs) equipped with more powerful electric motors were introduced a decade later. The first widely available PHEV was the 2011 Chevrolet Volt. The Volt boasted a 149-hp electric motor powered by a high-voltage lithium-ion battery, in addition to a small, 84-hp gasoline engine.

Today, battery electric vehicles (BEVs) are becoming the dominant alternative energy vehicles. BEVs have a fully electric powertrain—that is, they do not have an internal combustion engine at all but are powered solely by an electric motor fueled by rechargeable batteries. Early BEVs included the Tesla Roadster, introduced in 2008; the Nissan Leaf, introduced in 2010; and the Tesla model S, introduced in 2012. High-voltage lithium-ion batteries are the standard power source for BEVs.

There can be no doubt about the commitment of automakers to BEV’s. Ford recently announced an investment of $3.5 billion to build the country’s first automaker-backed LFP battery plant, offering customers a second battery technology within Ford’s EV lineup. Ford is now committed to building both nickel cobalt manganese (NCM) and lithium iron phosphate (LFP) batteries in the US. With this $3.5-billion investment, Ford and its battery tech collaborators have announced $17.6 billion in investments in electric vehicle and battery production in the United States since 2019, as part of the company’s commitment to invest more than $50 billion in electric vehicles globally through 2026. This commitment is similarly found throughout the transportation industry.

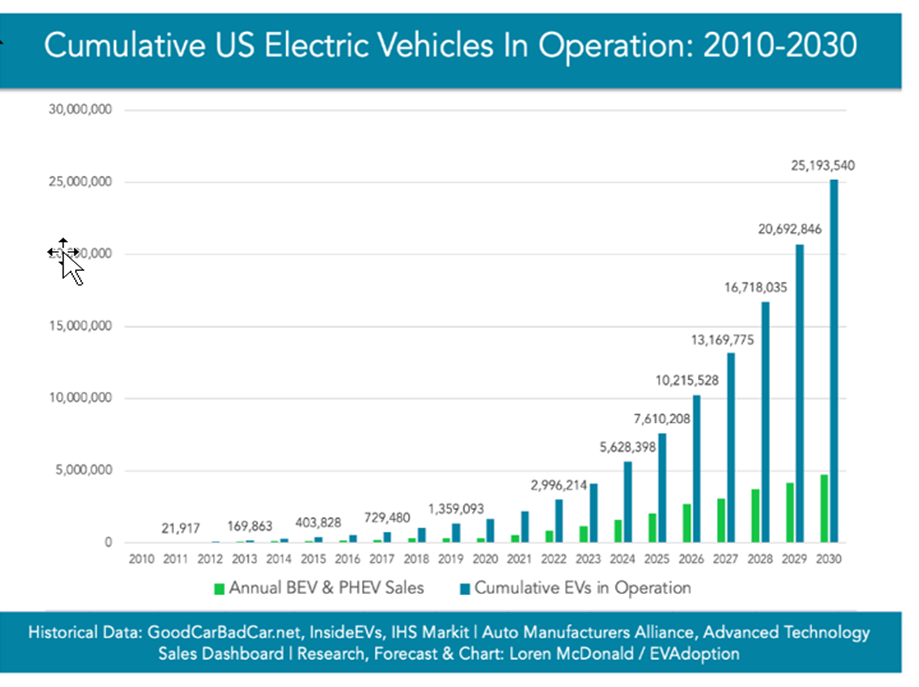

With rapidly growing sales volumes, the challenges associated with electromobility will become increasingly obvious. BEV sales volumes have increased fourteen-fold since their introduction, a trend that is expected to continue.[i]

Early BEV fires

When a Chevrolet Volt caught fire 3 weeks after a crash test in May 2011, safety concerns with the high-voltage lithium-ion batteries used in electric cars initially attracted attention.[ii] The National Highway Traffic Safety Administration (NHTSA), which monitored the crash test, looked into the origin of the fire as well as the possibility of fire in catastrophic collisions involving Volt automobiles. NHTSA investigated every complaint of a serious incident involving a Chevrolet Volt and found no evidence of battery fires caused by crashes in either a Volt or any other electric car. Chevrolet updated the design of the Volt’s battery housing to give increased resistance to collision damage even though the NHTSA identified no defects with the car. This was one early indicator of the challenges of BEV’s.

In 2017, a high-voltage lithium-ion battery caught fire when a BEV ran off the road and slammed into a residential garage at a high rate of speed, prompting the NTSB to conduct the first inquiry into electric vehicle battery fires on US highways. [iii]

By 2017, Tesla, had seized the dominant position in the electric vehicle market, and now sells roughly 80% of BEVs in the US. The NTSB reviewed three more high-speed, severe incidents between 2017 and 2018 that resulted in post-crash fires and one non-crash BEV fire, all of which involved Tesla-produced vehicles. The high-voltage lithium-ion batteries used in these cars presented different safety hazards to first and second responders over the course of the NTSB’s investigations than those posed by fires in vehicles with internal combustion engines.

The transportation sector was only starting to assess the safety of lithium-ion batteries at the time of the Volt incident. Prior to the Chevrolet Volt incident, the US Department of Transportation, the US Department of Energy, and NHTSA collaborated to create safer lithium-ion batteries for electric cars. This collaboration resulted in a scientific conference on lithium-ion battery safety that NHTSA sponsored. In order to “understand failure risks, establish safety techniques, and build performance-based metrics” for lithium-ion batteries, NHTSA had at that point created a multi-tiered research strategy. NHTSA continued to fund conferences in the years that followed when experts suggested areas for more study.

The National Highway Traffic Safety Administration (NHTSA) started working with the National Fire Protection Association (NFPA) in late 2011 to help first responders (firefighters) and second responders (tow operators) handle lithium-ion batteries after a crash. NHTSA was also developing post-crash procedures for handling vehicles powered by lithium-ion batteries with vehicle manufacturers.

The NFPA subsequently released the findings of a study on the risks that electric cars present to firefighters and emergency responders with an emphasis on the NiMH batteries that were then widely used. Best procedures for emergency responders to address dangers concerning the batteries in electric cars were developed and later, as part of its safety training program, the NFPA started releasing emergency field manuals for alternative fuel vehicles in 2015.[iv]

Lithium-Ion Batteries

High-energy batteries are necessary for BEVs which necessarily need to store a lot of energy, use it well, and discharge it quickly. For BEVs, lithium-ion batteries were selected because of their great electrochemical potential, high energy density (which enables them to store a lot of energy in a relatively small amount of space), and low self-discharge rate (allowing high-power discharge). In order to keep charging and discharging within safe limits, protection circuits are required, and all lithium-ion based systems rely on battery management systems to monitor and control battery function.

Lithium-ion based batteries include a liquid electrolyte which is flammable. Battery development is continuing, and “solid state” batteries are being developed which eliminate the potential for fires associated with liquid electrolytes. However, solid-state batteries have not yet been mass produced and currently almost all BEV’s include some form of lithium-ion based battery.

Like other batteries, lithium-ion batteries are made up of cells that convert chemical energy into electrical energy to create an electric current. Because they have a potential of 300 to 400 volts or more, lithium-ion batteries used in electric cars are referred to as high-voltage, with 800-volt electric vehicles either planned or currently available. In contrast, the well-known lead-acid automobile battery, which provides energy to start an internal combustion engine and to operate a vehicle’s auxiliary electrical equipment, has merely 12 volts.

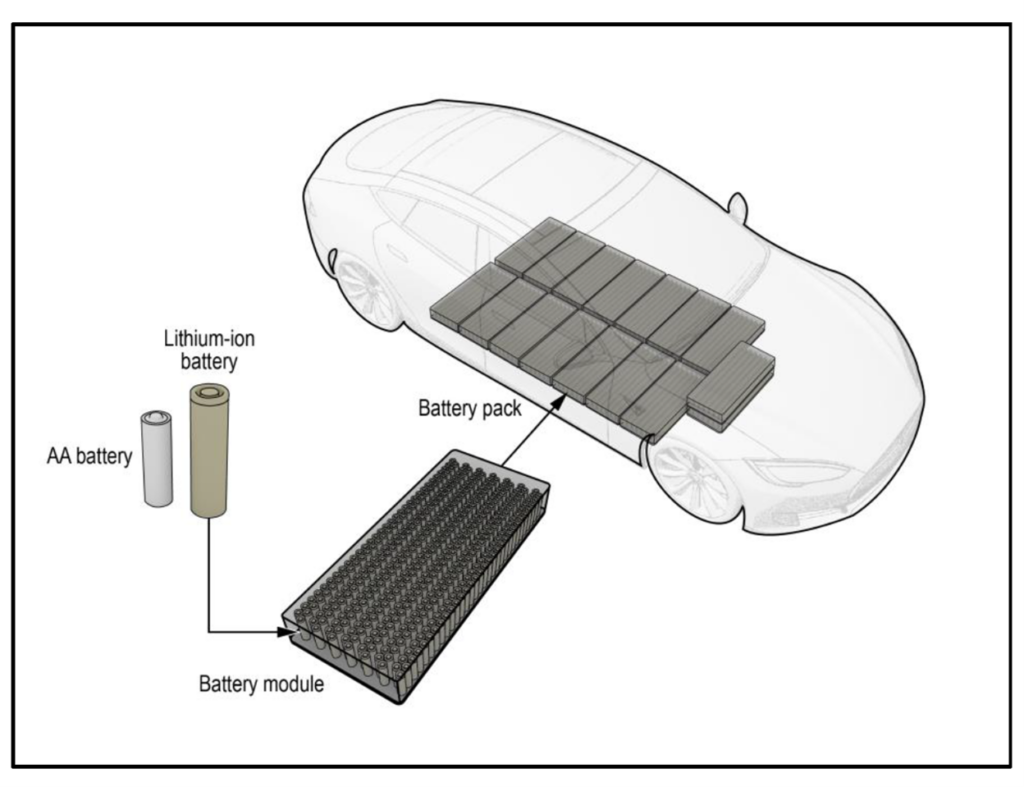

Different forms and sizes of lithium-ion battery cells are available (cylindrical, prismatic, elliptical, pouch). Individual cells are closely packed together to provide the necessary voltage, power, and energy in the battery of a BEV. Cells form modules and battery packs are in turn built from the cells. These batteries are enclosed in a housing that is designed to shield the batteries from collisions and to withstand damage from outside forces.

Battery management systems ensure that battery packs operate safely. The battery’s state-of-charge (level of charge in relation to capacity) is also monitored in addition to voltage and temperature data from the cells and modules to prevent overcharging or undercharging. Thermal management mechanisms built into the modules protect the cells from temperature extremes, and venting systems protect them from overpressure. Liquid cooling systems are included in several battery designs.

Direct current (DC) electricity is produced by lithium-ion batteries. Because electric vehicles are designed to convert AC power to direct current (DC), owners can charge their vehicles by plugging them into a 120- or 240-volt domestic alternating current (AC) socket. Commercial DC fast-charging facilities are another option for recharging the batteries. These stations allow for faster vehicle charging than a household outlet, which can take several hours.

The 2011 Volt Fire – an example of what can go wrong.

To ensure compliance with the Federal Motor Vehicle Safety Standards, in 2011 NHTSA conducted a crash test of a Chevy Volt. The crash test was conducted as part of NHTSA’s New Car Assessment Program (NCAP). NCAP is a federal consumer education program that assesses how well new car designs function in the face of safety concerns like collisions.

The Chevrolet Volt underwent a side-impact pole test in which a dummy was placed in the driver’s seat and the vehicle was subjected to a side impact into a rigid pole at a maximum speed of 20 mph. At the conclusion of the test, the vehicle was inspected to look for fluid leaks. The Volt received the highest crash safety rating—five stars—from NHTSA as a result of the test but unidentified problems remained.

The Volt test vehicle caught fire three weeks after the test when parked outside the testing site. Four nearby automobiles were damaged by the fire. Following inspection, it was determined that structural components of the vehicle body penetrated the battery compartment, damaged the lithium-ion battery, and ruptured the liquid cooling system for the battery. According to the incident report from NHTSA, the damage was not easily spotted by visual inspection and went unnoticed at the time of the test. The damage to the battery cells and the electric shorting, according to NHTSA, caused the fire.

NHTSA conducted another side-pole test on a different Volt in September 2011. There was no entry into the battery compartment, no cell breakage or shorting, no leaks, and no post-impact fire, hence the test did not have the same outcome as the original. No thermal or electrical activity was seen in the automobile or the battery throughout the following three weeks of monitoring.

The test was significant in revealing the challenges associated with BEV’s post-crash. The Volt did not see a thermal event until three weeks later and the damage to the battery compartment was not noticed upon inspection. When the damaged battery ultimately caught fire, it spread to nearby vehicles in part because the Volt was stored next to other vehicles (and potential fuel load) under the mistaken belief that it posed no risk.

Vehicle Occupants and First Responders

There are two main risks for occupants and first responders associated with lithium-ion battery-powered electric vehicles. First, the risk of electric shock from coming into contact with high-voltage connections in a broken battery. This is most commonly encountered by first responders. The energy that remains in a broken battery, known as “stranded energy,” is what causes the hazards of electric shock and battery reignition/fire. When the high-voltage battery is compromised in an accident and safety features like protective covers and circuit fuses are not effective, the high-voltage system of a BEV poses a safety risk. While the high voltage battery system is electrically isolated from the vehicle’s chassis in order to safeguard occupants, onlookers who come into contact with injured people, and emergency personnel from nonetheless are exposed to the risk electric shock from the stranded energy in the battery.

The second significant danger is the possibility of “thermal runaway” which occurs when damaged battery cells reach an uncontrollable temperature and pressure rises. Thermal runaway can result in hazardous gas venting and combustion, cell rupture and projectile release, battery ignition and fire involving both the vehicle and any surrounding fuel load.

Thermal Runaway

A chemical reaction known as “thermal runaway” generates heat (an exothermic reaction); the heat speeds up the reaction, raising the temperature and escalating the process. Thermal runaway can cascade from one battery cell to numerous battery cells. Thermal runaway often begins with a short circuit occurring inside a battery cell, which raises the temperature of the cell internally. A short circuit in a lithium-ion battery cell can be caused by manufacturing flaws like contamination or by the cell being crushed or punctured, which is the exact type of damage brought on by high-impact, high-severity car accidents. A battery cell could become heated enough by an outside fire to start a thermal runaway.

Cells that experience “thermal runaway” can burst into flames and explode. In the presence of extreme temperatures or electrostatic sparks, the flammable solvent in the electrolyte may catch fire. A “thermal runaway” is frequently accompanied by the release of flammable gases.

There are four main risks associated with “thermal runaway”: (1) toxic and flammable vapors released from the electrolytic solvent through pressure-relief devices or holes in the battery casing; (2) combustion of vapors released from the flammable electrolyte solvent; (3) localized overpressure; and (4) rupture of the cell casing and release of projectiles in the event that pressure-relief devices are absent or malfunction.

Asphyxiation of vehicle occupants from toxic gases released by the battery, release of toxic and corrosive chemicals, ignition and burning of combustible parts of the vehicle, and electric shock to occupants, first responders, or maintenance personnel from exposure to high-voltage conductors are all possible. Flammable gases like hydrogen, ethylene, ethane, and propane can all be emitted from a broken battery posing a fire risk.

To complicate matters, extinguishing a burning lithium-ion battery can necessitate using thousands of gallons of water. This aspect of lithium batteries is distinct from internal combustion engines and traditional vehicles. The efforts and resources needed to extinguish BEV fires can be far greater than that required for traditionally powered vehicles.

Recalls of EV’s for Battery Fire Risk

Automakers have already initiated recalls related to the risk of battery fires with a trend towards a growing population of vehicles being recalled.

|

Date |

NHTSA ID |

Covered Vehicles |

Vehicles Affected |

|

8/20/2021 |

21V650000 |

2020-2022 Chevrolet Bolt EV |

52,403 |

|

7/23/2021 |

21V560000 |

2017-2019 Chevrolet Bolt EV |

57,402 |

|

11/13/2020 |

20V701000 |

2017-2019 Chevrolet Bolt EV |

50,932 |

|

10/13/2020 |

20V630000 |

2019-20 Hyundai Kona Electric |

6,707 |

|

2/24/2020 |

20V107000 |

2019 Smart EQ |

1 |

|

6/10/2019 |

19V434000 |

2019 Audi e-tron |

1,646 |

Industry and Regulatory Actions

US-based and international organizations have released rules and specifications for electric vehicles and the high-voltage lithium-ion batteries that power them since the early 1990s. NHTSA, SAE International (SAE), and the National Fire Protection Association (NFPA) are three US organizations whose work focuses on the safety challenges associated with BEV’s.

Internationally, the International Organization for Standardization (ISO) and the United Nations Economic Commission for Europe (UNECE) are the most significant bodies addressing the risks of EV’s.

Federal Motor Vehicle Safety Standard 305 for US Vehicles

In the US, auto manufacturers are required by NHTSA to self-certify that a vehicle satisfies all Federal Motor Vehicle Safety Standards (FMVSS) performance requirements before it can be sold. Electric vehicles are explicitly addressed under FMVSS 305.[v] The standard was adopted in September 2000, concurrently with NHTSA’s involvement in the United Nations initiative to harmonize international standards for automotive safety. FMVSS 305 was initially designed to lessen the number of crash-related fatalities and injuries that can result from electrolyte spilled from batteries, electrical converters entering the passenger compartment, or electric shock.

The standard has several features:

- Within 30 minutes of a collision test and following a static rollover test, no more than 5.0 liters of electrolyte may pour outside the vehicle and no more than 5.0 liters may enter the passenger compartment (conducted after barrier crash tests).

- After crash tests, all electric energy storage or conversion equipment must be fastened to the vehicle and remain there by at least one anchorage.

- Each high-voltage source shall comply with one of the following three requirements: In order to be safe from electric shock dangers, it must either be electrically insulated from the vehicle’s chassis, have a voltage below what is considered acceptable (30 volts AC or 60 volts DC), or be physically surrounded to avoid direct human contact.

The standard covers passenger cars, as well as multipurpose passenger cars, trucks, and buses with a gross vehicle weight rating of up to 10,000 pounds, as long as they have electrical propulsion systems that can reach speeds of more 25 mph on a level, paved surface.

According to FMVSS 305, high-voltage batteries must be identified with a yellow triangle and distinct markings. Electrical connectors, electrical isolation barriers that cannot be accessed without tools, and the vehicle charge inlet are exempt from the requirement for labelling. Cables and parts that carry high voltage must be marked with an orange coating. There is no requirement that high-voltage cut loops or other methods of disconnecting the high-voltage system be indicated on a vehicle’s exterior. The procedure for cutting off the high-voltage power to the vehicle is not described in the specifications. The absence of such a standard leaves first responders facing varied challenges dependent on the make and model of the vehicle involved.

Potential Liability to First Responders

First responders face several risks from BEVs. The most notable, risk of electric shock. Comes from exposure to high- voltage connections in a damaged battery or vehicle. These same individuals also face a similar risk of exposure to thermal runaway events. Those thermal runaway fires involve chemical processes that produce both heat and toxic gases. Finally, the issue of stranded energy, voltage remaining inside an undamaged battery, also presents hazards.

NTSB studied these hazards ultimately issuing a report, “Safety Risks to Emergency Responders from Lithium-Ion Battery Fires in Electric Vehicles,” in November 2020. There NTSB reviewed emergency response guidelines from 36 manufacturers finding that all had ways to mitigate the risk of high-voltage shocks including methods for disconnecting the battery. However, none of the guides spoke of limiting the risk of stranded energy stored in the batteries. One way identified to deal with damaged batteries is to pull them from the vehicle and soak them in saltwater to discharge the energy.

Firefighters and other emergency workers who respond to events involving BEV’s are provided with voluntary recommendations by the more than 40 makers of electric or other differently powered vehicles. There are links on the makers’ websites to their emergency reaction manuals, the webpages of various makers as well as the NFPA guidance.

The NFPA has released a 460-page emergency field handbook (NFPA 2018), which is available for purchase and distribution on NFPA’s website. The NFPA and others created a film for the 2019 North American Heavy Rescue Conference that shows the best ways to handle electric car accidents. for purchase and distribution on its website. “Stranded Energy—How Little You Know Might Stun You” is an instructional film for firemen that the NFPA recently added to its website. The NFPA and others created a film for the 2019 North American Heavy Rescue Symposium that reflects best practices for addressing BEV fires.

The NTSB found that only two manufacturers’ emergency response manuals provide vehicle-specific information for putting out a high-voltage battery fire. Nearly all manufacturers’ emergency response manuals provide general information about the risks posed by the high-voltage lithium-ion batteries in electric vehicles, such as the fact that damaged batteries can ignite or reignite. All manufacturers should consider including important information such as when it is safe to cease applying water and where to apply water to put out a battery fire in a BEV.

Moreover, the NTSB noted that that none of the manufacturer guidelines they evaluated instructed emergency personnel on how to manage the dangers presented by the stranded energy in damaged high-voltage lithium-ion batteries. Risks associated with abandoned energy can affect tow truck operators who remove a BEV from the scene as well as firefighters who take part in the original emergency response.

According to SAE J2990, disabling an electric vehicle’s manual disconnect should not be the first method used by first responders to shut down high-voltage circuits. This is because (1) different designs make it difficult to locate and activate manual disconnects, (2) first responders are not always equipped with the necessary PPE, and (3) the manual disconnect may not be accessible.

Manufacturers of BEVs and the batteries included in them will continue to face potential risk of claims from first responders and bystanders who are confronted with these hazards. A renewed emphasis on instructions and training for first responders with specific strategies for addressing stranded energy and risk of electric shock should be a priority.

Potential Liability to Occupants

Automakers are quick to point out that statistically BEV’s pose no greater risk of fire than ICEs. The plaintiff’s bar counters that electric vehicles may not catch fire as easily, but any fire that does result from a compromised battery or as a result of an automobile accident poses the potential to burn far more intensely. Personal injury lawyers are quick to point out the growing volume of recalled vehicles with the suggestion that the batteries in these vehicles may present a hazard in the absence of an accident.

The high-voltage energy stored in lithium-ion batteries and the flammability of the batteries’ electrolyte create the potential for thermal runaway and fire. Thermal runaway begins with overheating in individual battery cells that degrades their electrical isolation and can be in progress even when flames are not visible outside the battery.

A difficult challenge lies in the effort to identify a potential thermal runaway event, inform the occupants of the vehicle that and provide an opportunity to get out of the vehicle. As noted, GTR 20 specifies both in-use requirements (covering normal vehicle use) and post-crash requirements. The in-use requirements address occupant safety for thermal events that can lead to fire, explosion, or smoke. Vehicles are required to provide advance warning of a hazardous situation inside the passenger compartment that will allow egress within 5 minutes.

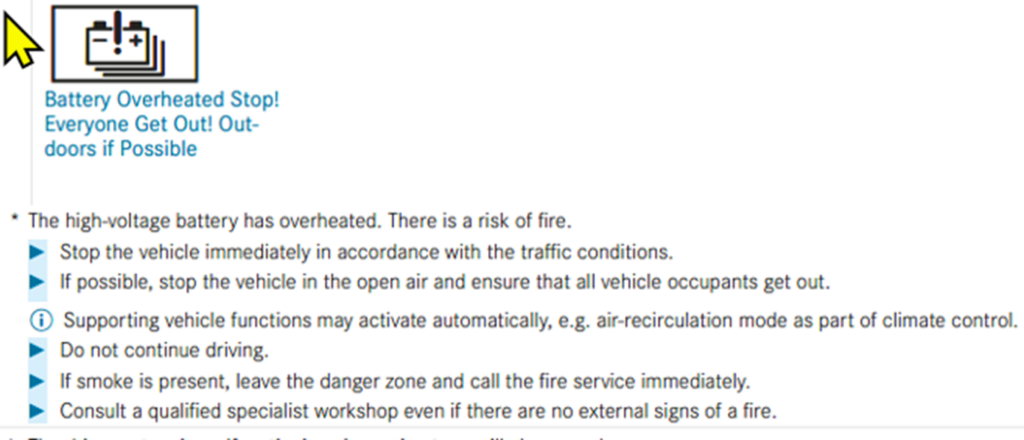

A properly functioning battery management system can detect the early signs of a potential for a thermal runaway event. Manufacturers are adopting strategies to comply with GTR 20 so that the occupants of the vehicle will have at least 5 minutes to get out of the vehicle before a thermal runaway event is imminent. Once the battery management system recognizes the potential through the measure of pressure and temperature, the challenge becomes effectively informing the occupants. Different manufacturers are adopting different strategies. Virtually all include information on the instrument cluster or driver information center that will inform the driver that the high voltage system has malfunctioned and that the risk of a fire is present.[vi]

The more difficult challenge is how to provide the five-minute window called for by the standard. To delay a thermal runaway event, battery management systems need to “open” battery connections. While this is one effective countermeasure to slow the progression of a thermal runaway event, it also depowers the vehicle propulsion system. Simply put, in order to delay the onset of fire, the vehicle must be disabled. Most manufacturers are adopting a strategy that will include a brief period of continued operation before propulsion is disabled. One can imagine a situation where a driver is on a busy Interstate and confronted with a warning that the vehicle faces a potential high voltage fire. The driver would then be informed that they have 30 seconds before the vehicle will shut down. The driver must then not only appreciate the instruction would take immediate steps to move the vehicle to a safe location before the propulsion system is shut down.

[i] https://evadoption.com/ev-sales/ev-sales-forecasts/

[ii] https://www.just-auto.com/news/us-volt-fire-prompts-nhtsa-probe/

[iii][iii] NTSB case number HWY17FH013)

[iv][iv] https://www.nfpa.org/Training-and-Events/By-topic/Alternative-Fuel-Vehicle-Safety-Training

[v] FMVSS 305, codified at Title 49 Code of Federal Regulations (CFR) 571.305, was adopted in September 2000 and was effective on October 1, 2001 (65 Federal Register 57980). Its full title is “Electric-Powered Vehicles: Electrolyte Spillage and Electrical Shock Protection.” The standard applies to passenger cars and to multipurpose passenger vehicles, trucks, and buses with a gross vehicle weight rating of ≤ 4,536 kilograms (10,000 pounds) that use electrical propulsion components whose working voltages are more than 60 volts DC (or 30 volts AC) and that can attain a speed greater than 40 kilometers per hour (km/hr; 25 mph) over a distance of 1.6 km (1 mile) on a paved level surface.

[vi] 2023 Mercedes EQS Sedan warning